Product Name:Single Screw plastic pelletizing machines (HQ-90)

Model: HQ-90

Different models of screen changers:

Two-bolt, two-cavity hydraulic screen changer: more efficient production.

Single-plate hydraulic screen changer: easier and simpler to change the screen.

Manual screen changer: to obtain a more consistent quality of plastic pellets, but requires manual operation.

Extruder screw options:

1. Special screw for PC.

2. Universal screw: extruder can work on different plastics: ABS/ AS/ COC/ EVA/ LCP/ PA/ PBT/ PC/ PE/ PEI/ PET/ PMMA/ PP/ PS/ PVB/ PVC etc.

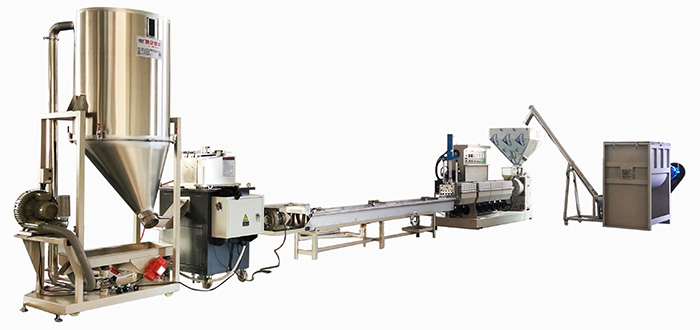

Single Screw plastic pelletizing machines line:

Single screw Plastic Extruder

Water cooling tank with suction motor

Plastics Pellets Cutting Machine

Plastics Vibrating Machine with Hopper

Screw Loader (Option)

Vertical plastic mixer (Option)

Horizontal Plastic Mixer (Option)

Advantages of the Single Screw plastic pelletizing machines line:1. Machine with frequency converter (VF), power saving. Saves approximately 25% to 30% of electricity compared to normal plastic granulators.

2. The machine does not destroy the MFR in the PC and does not change the color of the raw material.

3.No more than 8% of additives (including titanium dioxide, color masterbatch, light diffusion powder, etc.) can be added during the production of this granulator, without affecting the quality of the final product.

Technical Data (Extruder)

| Model No. | HQ-45 | HQ-65 | HQ--90 | HQ-105(High speed) | HQ-120 | HQ-150 |

Capacity (PC+ABS)

| 20-50KG/HR | 80-130KG/HR | 200-300KG/HR | 400-600KG/HR | 400-600KG/HR

| 600-1000KG/HR |

Install Dimension (mm)

| 2300*880*1500 | 3200*1000*1800

| 4500*1800*2100

| 5600*1400*1900

| 5600*2400*2500 | 6500*2800*2500 |

Total Weight

| 1500KG | 1800KG

| 2800KG

| 4800KG

| 5100KG

| 6200KG

|