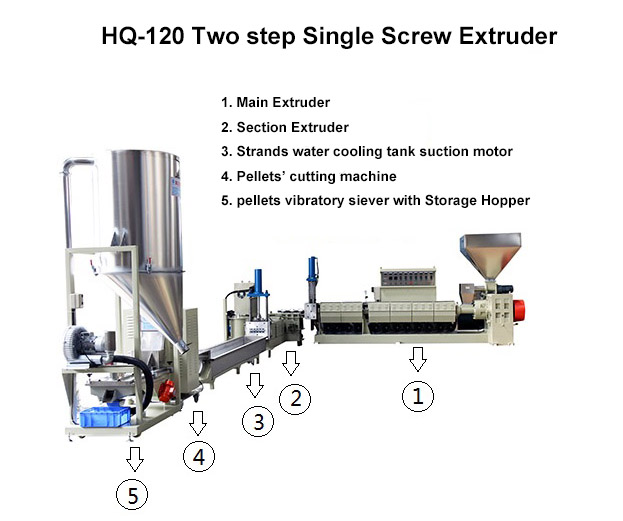

Product Name:Two step Single Screw Extruder Production line

Model: HQ-120T

Two step Single Screw Extruder

Application (Two step Single-screw extruder)

For all kinds of plastic scrap, ABS, PC, PA, PE, PP, or any others waste plastic material.

Especially for the dirty material for make pellets.

Main Extruder for Two step Single Screw Extruder(HQ-120)

1. Screw: Screw dia. Φ120mm, L/D:32

2. Material: SACM-1, Chrome-plated or SCM-4 bimetallic

3. P.I.D. thermo controller: 7 zones

4. Gear oil cooling filter system: 1 group

5. Barrel air cooling:1/4HP×12 sets ( auto start)

6. Screen changer: Hydraulic, 4KW(260mm, two filter ) machine non stop change screen mesh.

7. Main Motor: 110KW, VF-variable frequency inverter driven

8. Machine size(mm): 4920*2400*2300

Section Extruder(HQ-130)

1. Screw: Screw dia. Φ130㎜, L/D:8

2. Material: SACM-1, Chrome-plated or SCM-4 bimetallic

3. P.I.D. thermo controller: 4 zones

4. Screen changer: Hydraulic,

5. Section motor (AC): 30KW VF

8. Machine size(mm): 2750*1500*1800

Water cooling tank with suction motor

1. Material: stainless steel

2. Suction motor: 2.2 KW

3. Machine size(mm): 5000*450*300

Pellets Cutting Machine (HQ-1000C)

1. Motor: 7.5 KW VF

2. Stationary knife: Tungsten steel

3. Rotary cutter: Tungsten steel or SKD-11, 28 blades

4. Stationary knife: Tungsten steel

5. Machine Weight: 500KG

6. Machine size(mm): 960*870*1350

1. Vibration motor: 1/4 HP*2

2. Feeding motor: 3 KW

3. Material: #304 stainless steel, 3 layer

4. Filter dia.: top Φ6.5mm, down Φ2mm*20L

5. Mix capacity: 500 KG

Option Machine for Two step Single Screw Extruder

Adjustable Speed Feeding Hopper (HQ-110A)

1. Material: stainless steel

2. Screw dia.:Φ94

3. Speed reducing ratio: 40:1

4. Reducer motor: 1.5 KW, VF inverter driven

5. Hopper capacity: 100-650 KG/H

6. Machine size(mm): 730 x 730 x 1050

Two step Single Screw Extruder series

HQ-120T

HQ-150T