Product Name:Plastic Crusher

HongQi plastic machinery manufactures is strong plastic crusher shredder china supplier.

Youtube video: https://youtu.be/zhhtI67O9h4

Machine introduction:

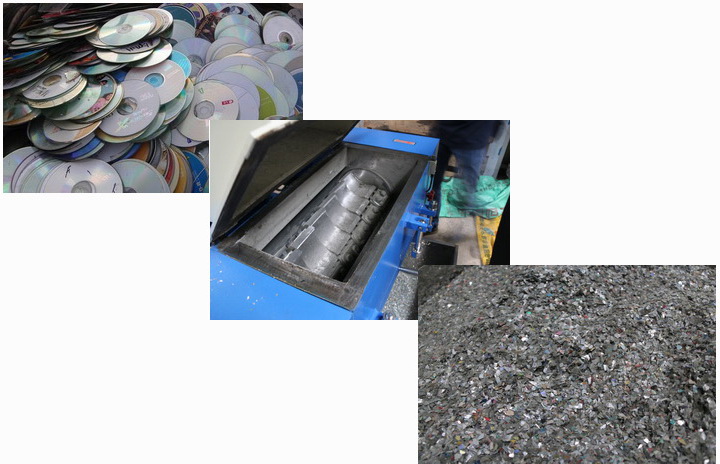

Plastic crusher, also call plastic shredder. Plastic crusher is mainly used for crushing all kinds of plastic and rubber, such as plastic profile, pipe, bar, silk, film, scrap rubber products. Granules can be used directly for extruder or injection molding, can also be used through the basic granulation regeneration. There is also a plastic crusher is the peripheral equipment of injection molding machine, you can break the recycling machine produced by the defective products and the mouth of the machine.

Working principle:

Plastic crusher through the motor running with the knife of rotary high-speed rotation. In the process of rotary and the fixed knife high-speed rotation come into being relative movement trend.When the rotary and the fixed knife work make the space, resulting in plastic crushing cut incision. Which will be broken pieces of plastic, The broken plastic through the screen filter output.

Application:

Can be used for box, thin pipe, blow molding pieces, bottles, shells and other waste plastics recycling or recycling as a machine or other auxiliary machine injection molding machine nozzle material or sub-pieces of re-use.

Classification:

A. Hard plastic crusher

1. ABS, PE, PP board and other plate crushing recovery.

2. For the board material crushing and the design of the rectangular design of the mouth, easy to strip into the slab, improve work efficiency. Optional suction fan, storage tank composition of the plate crushing recovery system can be more fully play the recovery efficiency.

3. With a sealed bearing, so that the bearing rotation for a long time to maintain a good; knife design is reasonable, the product into a uniform; knife seat heat shrink treatment, shape design nice.

B. Strong plastic crusher

1. Chip-type knife structure between the claw knife and flat knife, suitable for breaking ordinary sheet, pipe, profiles, sheet metal and packaging materials and other plastic products.

2. General-type plastic grinder, with a sealed bearing, so that the bearing rotation for a long time to maintain good. Knife design is reasonable, with alloy steel blade, the product into a uniform grain. Knife seat heat shrink treatment, and after a rigorous balance test, nice appearance design.

C. Plastic pipe plastic crusher

1. Suitable for crushing all kinds of small and medium-sized plastic pipe, such as PE, PVC pipe, silicon tube and other pipe crushing recovery.

2. For the tube material crushing and unique design of the tube-type feed port, easy to strip into the pulverized, improve work efficiency. Optional suction fan, storage bucket composition of the pipe crushing and recovery system can be more fully play the recovery efficiency.

Knife classification:

Claw knife crusher

Applicable to all kinds of plastic crushing and reusing, especially for all kinds of rigid plastic. (Such as material head, shoe last material, etc)

Feature:

1. High efficiency and low energy consumption.

2. The screen can be replaced according to the crushing thickness.

3. Simple operation, easy to replace the blade and screen, safe and easy maintenance.

4.The electric motor has over-loading protection with power source interlock protection Device. Double-safety protection for operators and electric motor.

5. The plastic crusher are structure compact, strong rigidity, safe and reliable. Use high-intensity steel screws to fasten the knife leaf and knife seat, having strong Bearing capacity.

6. Applicable to dry, wet plastic and waste plastic. Widely use in recycling waste plastic business. Can broken board material; Tube material; Form material and big plastic product.

7. The knife tool is refined with imported special tool-steel, the clearance between Knife tools are adjustable, when it becomes blunt by using, it can be dismounted Repeatedly, it is durable.

Parameter:

Model

| Motor capacity

| Motor speed

| Knife speed

| Weight (KG)

| Size(mm)

|

| HQ-400 | 11-15KW

|

|

| 850

| 1600*1080*1400 |

HQ-600

| 30KW | 1480R/Min | 500R/Min | 1800 | 1500*1750*1680 |

| HQ-600E | 30~37KW | 1480R/Min

| 500R/Min

| 2200 | 1500*1750*1680 |

| HQ-600S | 30~37KW | 148R/Min | 500R/Min | 2200 | 1700*1500*1800 |

| HQ-800 | 35~40KW |

|

| 3000 | 2000*1800*2150 |